JFETIGERTM

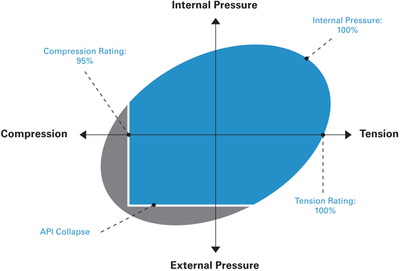

JFETIGERTM been designed and tested to meet the needs for critical well loads. The design incorporates metal-to-metal seals with a 17° internal torque shoulder to ensure sealing under extreme loads. The negative load flank thread form and coupled design provide 100% tension efficiency for the standard coupling.

Special clearance coupling OD’s are available with full pipe body internal and external pressure ratings.

Designed for performance

- Run-out pin thread and coupling provide 100% pipe body tension

- Standard and special clearance coupling ODs

- Carbon steel and Chrome grades

- Streamlined ID profile design

- Tested with ISO 13679 2002 and DIS 2009 and field-proven

| DESIGN | ADVANTAGE | |

|---|---|---|

| Reduced gap between stabbing flanks on the pipe and coupling thread. | ⇒ | Increased resistance to damage from compressive loads. |

| Negative load flank angle on threads. | ⇒ | Increased tensile and bending capacity while maintaining gas tight seal. |

| 25° angle for thread stabbing flank. | ⇒ | Quick make up and increased resistance to cross threading. |

| Different corner radius for load flanks for pipe and coupling threads. | ⇒ | Increased resistance to galling. |